PUNI

DISTILLERY

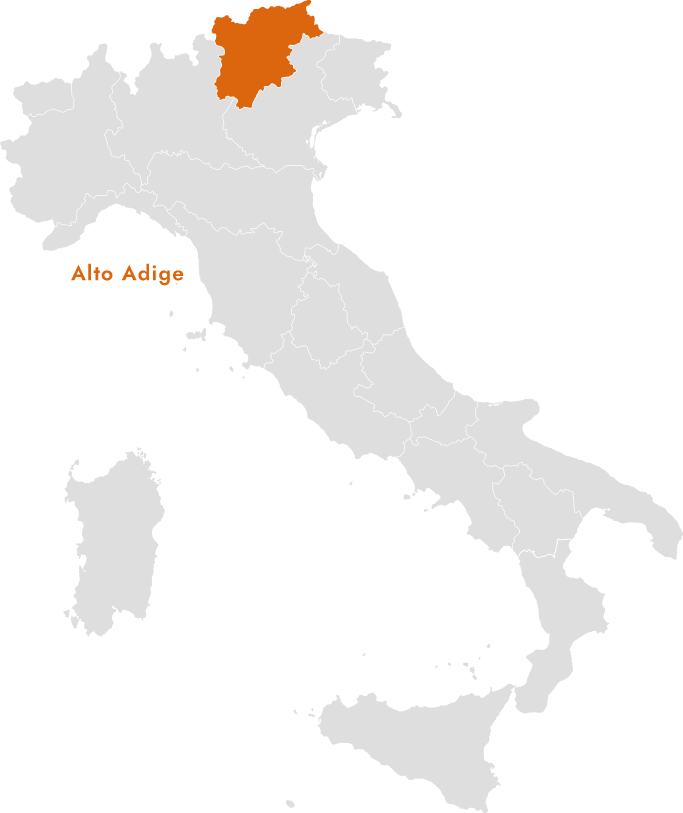

Glorenza, Alto Adige (BZ)

Glorenza, Alto Adige (BZ)

The tagline says it all: “The Italian Malt Whisky.” Then again, there’s so much more to be said about PUNI. It’s Italian, yes, but also German and, perhaps most of all, Alpine. This pioneering whisky distillery, the first of its kind in Italy, takes its name from the nearby PUNI River, which originates in the Ötztal Alps and flows through the magnificent Venosta Valley. From the Medieval hamlet of Glorenza, where the PUNI Distillery is located, both the Swiss and Austrian borders are less than a half hour away.

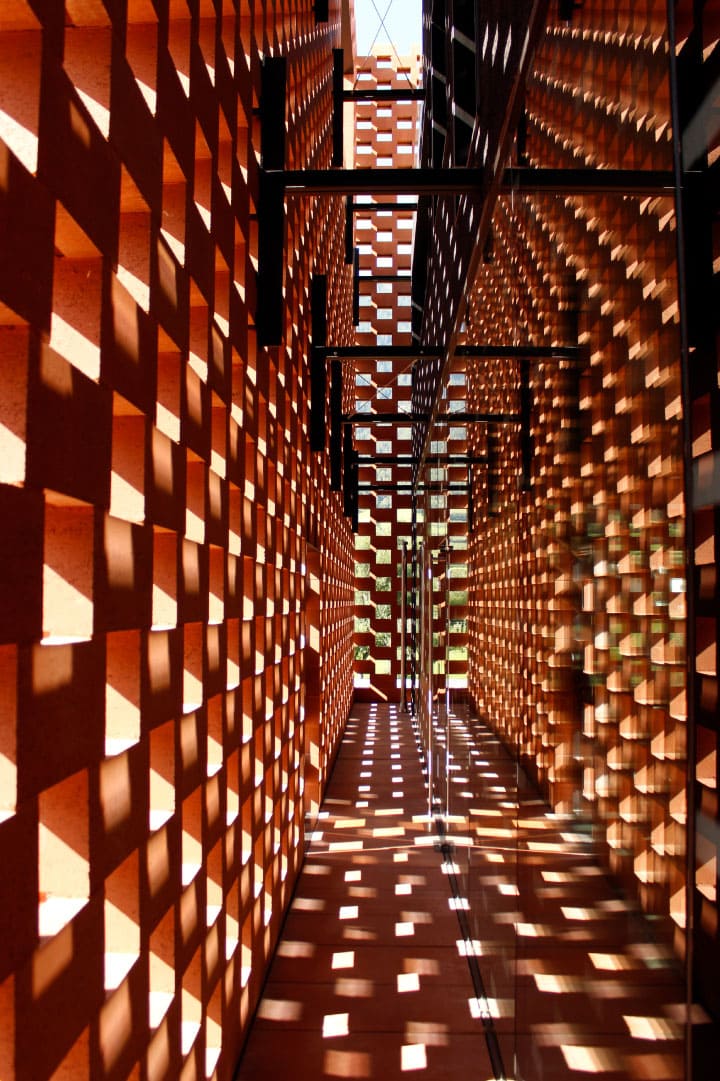

The Ebensperger family founded PUNI in 2010, partnering with local architect Werner Tscholl to create the compact, 13-by-13-meter cube that houses the entire operation.

Crafted from red concrete blocks and modeled on the design of traditional barn windows in the Alto Adige region, the PUNI “cube” is found just outside Glorenza’s city walls; it’s a new landmark in a picturesque town already recognized as one of the Borghi Più Belli d'Italia (an official association of the most beautiful villages in Italy).

The Ebenspergers, Albrecht and Jonas, took inspiration from the historic distilleries of Scotland when creating PUNI: The copper-pot stills were hand-fabricated in Scotland by the venerable firm Forsyths, and, just as Scotch distilleries have Gaelic names, PUNI is an ancient Rhaetic name, bestowed on the namesake river by local Alpine tribes in pre-Roman times. More than anything, however, the connection to Scotland and Scotch Whisky is more philosophical than literal: PUNI’s whiskies are authentic representations of their place, which the Ebenspergers like to call “The Italian Highlands.”

More specifically, these Italian Highlands are the northwestern corner of Italy’s Bolzano province, also known as the Alto Adige, or Südtirol. This is “Tyrolean” Italy, mostly German speaking and mountainous, its canyons carved by the Adige River and its tributaries. Temperature swings between summer and winter up here are dramatic, which accelerates the barrel maturation process and lends even a four-years-aged whisky an exceedingly mellow, mature character. Much like Scotch, the PUNI range is aged in a variety of casks, including ex-Bourbon barrels from the US; Sherry casks from Spain; and used wine casks from Italy, most notably barrels that previously held Sicilian Marsala.

The Venosta Valley, or Vinschgau, has long been known for its grain production—although the principal crop of the region has traditionally been rye, not barley (rye being better suited to the dryer climate here). The original mash bills for PUNI products included some locally malted rye along with malted barley and wheat from other sources. Since 2016, they’ve also produced more “classic” malt whiskies from 100% malted barley, which is sourced from Italy, Germany, and even Scotland. Since releasing their first products in 2015, PUNI has racked up an impressive list of accolades from the press and international spirits competitions, including a “Best European Whisky” nod in the 2021 edition of Jim Murray’s Whisky Bible.

Having already established a foothold in the US market, the PUNI whiskies are well-positioned for breakaway success as part of The Italian Spirits Company portfolio. There’s no better example of spirits expressing terroir than these impeccably crafted, artfully packaged malt whiskies—bright, fragrant, finessed styles that reflect their Alpine origins.

To understand why we invested a significant amount of time, thought and resources in order to plan and build our custom heating system, it’s important to know a bit more about what happens during distillation.

In essence, distillation is a method of separating a mixture of liquids within a controlled system through the application of energy in the form of heat.

The addition of heat is the crucial human touch. To narrow it down, the better the control of temperature, the better the control over the outcome of distillation.

For example, when a malt mash is scorched or burned during distillation, it can produce a range of undesirable compounds that impart negative flavors to the final product. One is furfural, which is formed from the degradation of sugars under high heat, contributing a bitter and burnt taste. Then there’s hydroxymethylfurfural, which arises from the thermal breakdown of carbohydrates, leading to off-flavors reminiscent of burnt caramel. Acrolein is another compound that may be formed through the degradation of glycerol, adding an acrid odor and taste.

To erase the risk of scorching and to have almost full control, we implement a special bain-marie system, where superheated water runs through stainless steel pipework inside the still, rather than using a traditional heating jacket. This system allows for more precise control over the heat transfer.

The energy transfer from superheated water to the medium inside the still is usually gentler and more uniform compared to using steam. Steam heating can sometimes create hotspots and uneven temperatures, raising the risk of scorching. Moreover, steam heating is less nuanced, typically operating at extreme modes: either fully on or completely off.

In contrast, the superheated water in our system can be regulated within a temperature range of approximately 95°C to 135°C in 0.5°C increments (although that's not necessary), allowing for precise control over the distillation process.

In our distillation process, precise temperature control is crucial across various stages, ranging from heating up, foreshots, heart run, to tails, each at more or less specific temperatures. For instance, during the foreshots stage, we lower the temperature below 100°C for a specific duration to effectively separate undesired compounds. The heart run stage is particularly nuanced, utilizing three distinct set temperatures to meticulously isolate the desired parts.

The downside of the whole thing: our distillation process takes longer time, reaching up to 12 hours per run, and results in higher costs due to the extended operating hours, etc. Our yield is also lower compared to traditional Scottish distilleries, due to narrower cut points.

On a positive note, by utilizing a highly efficient wood chip oven, our operation is nearly CO2 neutral.